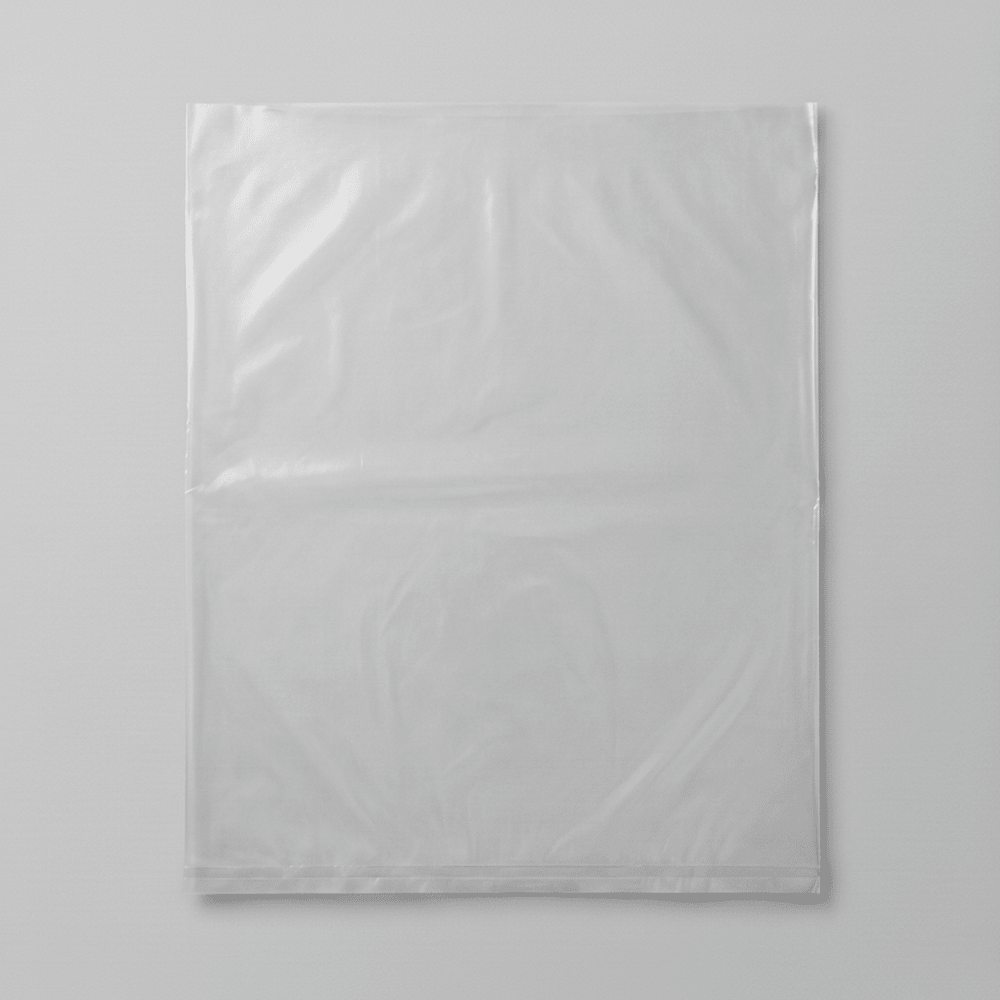

Dissolvable 120 Litre Bin Liner

Couldn't load pickup availability

Reduce your waste disposal costs

Eliminate contact with hazardous waste

Reduce your impact on the environment

Simplify your packaging ordering

Eliminate bin odours and contamination risk with water soluble bin liners. This premium PVOH liner dissolves completely in digesters above 60°C alongside organic waste, removing the need to handle contaminated plastic or clean soiled bins. The 120 litre capacity handles heavy food waste without tearing during collection and transport.

Designed for commercial kitchens, healthcare facilities, aged care, and hospitality venues processing organic waste through digester systems, these liners streamline waste handling while eliminating plastic contamination in processing systems.

At a Glance

| Specification | Details |

|---|---|

| Material | Premium PVOH film |

| Capacity | 120 litres |

| Dimensions | 1200 mm x 900 mm |

| Strength Rating | 3x stronger than LDPE |

| Dissolution Temperature | Above 60°C |

| Closure Type | Open top |

| Pack Size | 25 liners per pack |

| Carton Quantity | 200 liners (8 packs) |

| Testing | Trialled with commercial digesters |

| Delivery | Fast Sydney dispatch |

Perfect for: Commercial kitchens, hospital food services, aged care facilities, hotels, and hospitality venues processing organic waste through digester systems.

Our policy lasts 30 days. If 30 days have gone by since your purchase, unfortunately we can’t offer you a refund or exchange.

To be eligible for a return, your item must be unused and in the same condition that you received it. It must also be in the original packaging.

RefundsOnce your return is received and inspected, we will send you an email to notify you that we have received your returned item. We will also notify you of the approval or rejection of your refund.

If you are approved, then your refund will be processed, and a credit will automatically be applied to your credit card or original method of payment, within a certain amount of days.

Sale itemsOnly regular priced items may be refunded, unfortunately, sale items cannot be refunded.

ShippingTo return your product, you should mail your product to: DB Packaging Pty Ltd, Unit 3, 3-7 Carnegie Place, Blacktown NSW 2148

You will be responsible for paying for your own shipping costs for returning your item. Shipping costs are non-refundable. If you receive a refund, the cost of return shipping will be deducted from your refund.

Depending on where you live, the time it may take for your exchanged product to reach you, may vary.

If you are shipping an item over $75, you should consider using a trackable shipping service or purchasing shipping insurance. We don’t guarantee that we will receive your returned item.

Recently Viewed Products

- $0.00

- $0.00

- Unit price

- per

- $0.00

- $0.00

- Unit price

- per

- $0.00

- $0.00

- Unit price

- per

- $0.00

- $0.00

- Unit price

- per

- $0.00

- $0.00

- Unit price

- per

- $0.00

- $0.00

- Unit price

- per

- $0.00

- $0.00

- Unit price

- per

- $0.00

- $0.00

- Unit price

- per

- $0.00

- $0.00

- Unit price

- per

- $0.00

- $0.00

- Unit price

- per

- Choosing a selection results in a full page refresh.